What is the production process of industrial aluminum materials told by the industrial aluminum material manufacturer?

aluminum profile is an alloy material mainly composed of aluminum. Melt extrusion is performed on the aluminum rod to obtain aluminum materials with different cross-sectional shapes. Industrial aluminum melting and casting is the first process in the production of aluminum profiles. The specific process is as follows:

- Composition of industrial aluminum profile: Industrial profile factories calculate the addition amount of various alloy components according to the specific alloy grades produced, and reasonably match various raw materials.

- Melting: Industrial profile factories place the prepared raw materials into the smelting furnace according to process requirements for melting, and effectively remove slag and gas from the melt through degassing and slag refining methods.

- Casting: Melted aluminum liquid is cooled and cast into various specifications of round cast rods through a deep well casting system under casting process conditions.

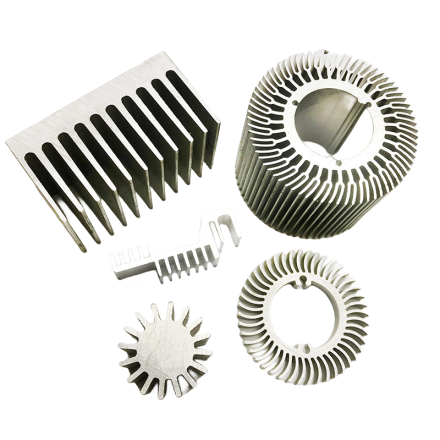

- Extrusion: Extrusion is a method of forming profiles. Firstly, design and manufacture a mold based on the cross-section of the profile product, and use an extruder to extrude the heated round cast rod from the mold. Commonly used grades 6063 and 6061 alloys also use air cooling quenching process and subsequent extrusion artificial aging process to complete heat treatment strengthening.